There are three occasions when you need to wear a respirator:

- You are likely to breathe a nasty volatile chemical.

- You are likely to breathe a nasty dust.

- You are likely to breathe a nasty volatile chemical AND a nasty dust.

This will happen a lot!

One of the main problems with building things out of composites is that most of the materials are poisonous or have the potential to damage our bodies in some other way. Volatile chemicals and dust are part of the day-to-day work of the composite industry and you need to protect yourself!

The Respirator

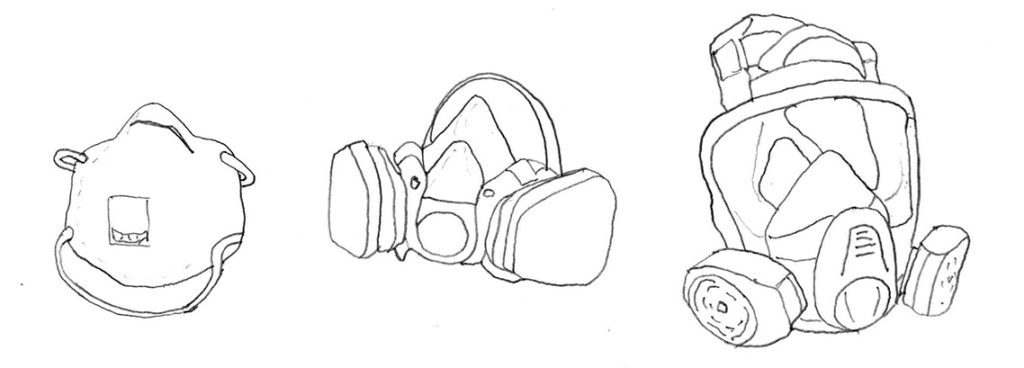

A respirator is a mask that filters the air you breathe in. There are three main types you’ll encounter – and one of these isn’t really a respirator!

Up first ladies and gentlemen, we have the lowly dust mask – hardly a respirator! And in the middle – the trusty half-mask – great for you glasses-wearers. On the right – for when you’re doing something genuinely nasty – we have the full face respirator!

These three, er… these two are great for protecting your lungs. The dust mask, well that’s ok for running some pine through the table saw or sweeping the kitchen floor at home, but it doesn’t offer enough protection for industrial use. If you’re mixing fillers or running a wet-out machine or sawing some G10, you’re going to want the protection that a real respirator provides! The reason dust masks aren’t up to serious particulate challenges is that they don’t conform to your face very well. Respirators always have a seal and strap combination that holds tight to your head and doesn’t allow air to leak around – because that air has nasty stuff in it – and even a little is bad.

That said, if a dust mask is all you have – wear it! The Covid-19 pandemic has made high-quality respiratory masks (N95 or similar) very common and easy to get. They will help to protect your lungs, just not as well as an industrial respirator will.

And if you’re really going nuts in a nasty environment, powered air respirators are an excellent – if expensive – choice. They have the added advantage of blowing cool clean air into your face which is comfortable and excellent for glasses – wearers.

Filters: Particulate vs. Organic Vapor

Those real respirators almost always have modular filters that can be removed and swapped out for different kinds of protection. There are two general kinds of protection you will need when doing composites-related work.

When dust is your problem, you need particulate – for particles – filtration. These filters are made up of layers of fine mesh that lets air through but doesn’t let particles through. When you breathe in, you get air but the particles stay stuck in the filter. Respirators usually have one-way valves that allow you to exhale directly without pushing air out through the filters again. You can feel the slight resistance breathing in through a respirator – but you get used to it.

When you are using bad smelling stuff like resins, paints, solvents and mold releases what you need are organic vapor (OV) filters. These use activated charcoal combined with filters to absorb the nasty stuff. They have a limited window for use and will run out of activated charcoal after a specified period. The should also be kept sealed in a bag when not in use. Check the instructions that come with your respirator to see how to store it’s parts safely.

And then there are times when you need both kinds of protection – #3 on the list. Fortunately most respirators can use combined filters or can stack filters using a special adapter. The dust filters go outside the OV filters and you get full protection for your lungs.

Respirator Fitting

If you work at a big company with a safety team or officer, you will likely be fitted for any respirator that you need. This involves smelly stuff and a bag over your head and all it really does is make sure you have the right size mask and that it is adjusted to fit your face.

For an idea what is involved, here is a link to a video: 3M Respirator Fit Kit Test Video

If you are fitting it yourself, do everything to make sure you don’t have air leaks. You can place your hands over the holes where the canisters attach (with them removed) and feel it suck onto your face when you inhale. This is a start, but if you are doing serious dust or chemical exposure, it is probably worth reading your respirator’s instructions, doing some online research and making sure you have it right.

A note on beards: they don’t work very well with respirators. Typically to be fit for a respirator you must be clean-shaven and this creates a problem because beards are so fashionable! The only good solution is a powered-air respirator with a hood and an external filter pack. These cover your head and provide a positive pressure to your face area keeping all the nasty stuff out. They are expensive and awkward to wear sometimes, but they are worth considering if you have a beard or glasses and do a lot of respirator-required work.

Respirator Storage

Respirators should be stored in a clean air-tight box. Leaving your respirator around to get all dirty kind of defeats the purpose. It is also a violation of safety rules (and laws!) in many places to leave a respirator laying around. You should also avoid leaving it hanging around your neck by the bottom strap. I know it’s handy and I have done it myself more times than I care to admit – but not you – you can do it the right way!

And finally, you should clean your respirator now and then, especially if you ever put it on and it smells moldy or otherwise bad. Most can be run through a dishwasher with the filters removed – but beware the gaskets that are easy to misplace. For more frequent cleaning, use respirator cleaning wipes that come in a little foil pouch. There’s nothing like a fresh clean respirator!

The Law

If you run a business and have employees who’s work requires respirator use, you can’t neglect your responsibility. You probably already have a safety program that covers respirator use and your team knows when and how to use respirators safely – but here’s a little light reading from OSHA just in case:

OSHA 3384 SMALL ENTITY FOR RESPIRATORY PROTECTION STANDARD REV 9.28.11