EC! Home: Articles: Tools and Equipment: How to Choose a Vacuum Pump for Composites

Updated: 5/7/21

By: Chris

A vacuum pump is necessary equipment for many types of composite processes. There are a lot of choices and prices and ways to get your hands on one, and if you are doing large projects or commercial work, you’re going to want a few. This article discusses the options and my opinions on what the best choices are for different types of composites work.

Questions to ask yourself before you dive in:

- Why do you need a vacuum pump?

- What types of composite processes are you going to be doing?

- How much pump do you need? Think in terms of: power (hp), volume (CFM or m^3/hr), maximum vacuum level (inHg, torr, millibar)

- How much money can you spend?

This article and video include six small example pumps from my “collection.” These are all of common types that can be good for use in a variety of composites processes. Many brands make similar pumps and there are tons of them available new and used in a wide variety of conditions. We’re going to look at how they compare and what qualities you need in a pump for your type of work.

You may also like these other articles:

Table of Contents

- About Vacuum

- Use Cases

- Types of Pumps

- Example Pumps

- Pumps for Vacuum Infusion

- Buying a Pump

- Brands

- Power and Setup

- Other Equipment

- Conclusions

Video

So here’s a video that goes with this article. It covers many of the same things and shows six actual pumps. The article has more in-depth information though! Charts from the video are shown below in the ‘Example Pumps‘ section.

Video: How to Choose a Vacuum Pump for Vacuum Bagging Composites

About Vacuum

First a bit about vacuum in general. Vacuum is just volume without any molecules in it. The reason a vacuum bag presses “down” on its contents is that the atmosphere (air, sky, all the clear stuff up there) weighs a whole lot. We don’t feel it because we are “pressurized” from the inside to compensate and our bodies are designed to handle it. If you go way up in the air in a plane where there’s less pressure, the plane is pressurized to approximate the way it feels on the ground. This is why astronauts wear pressurized suits while space-walking!

So when you pull the air out of a vacuum bag, there is no more air pressure inside. The atmosphere outside presses down on the outside of the bag with its full weight, which is approximately 14.7 lbs per square inch – or about 10,300 kg per square meter (101 kPa). That’s a lot! We can measure the amount of air removed from a vacuum bag relative to the air outside (atmospheric pressure) with a relative vacuum gauge. If you remove only some of the air inside a vacuum bag, the atmospheric pressure only pushes with a fraction of the potential 14.7 psi / 101kPa. So you can adjust the vacuum level to tailor the pressure required for the job.

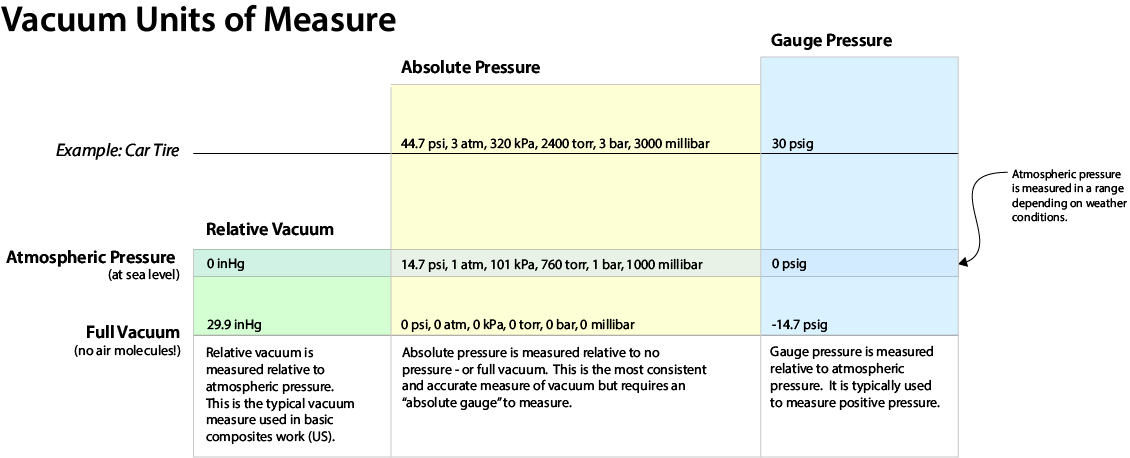

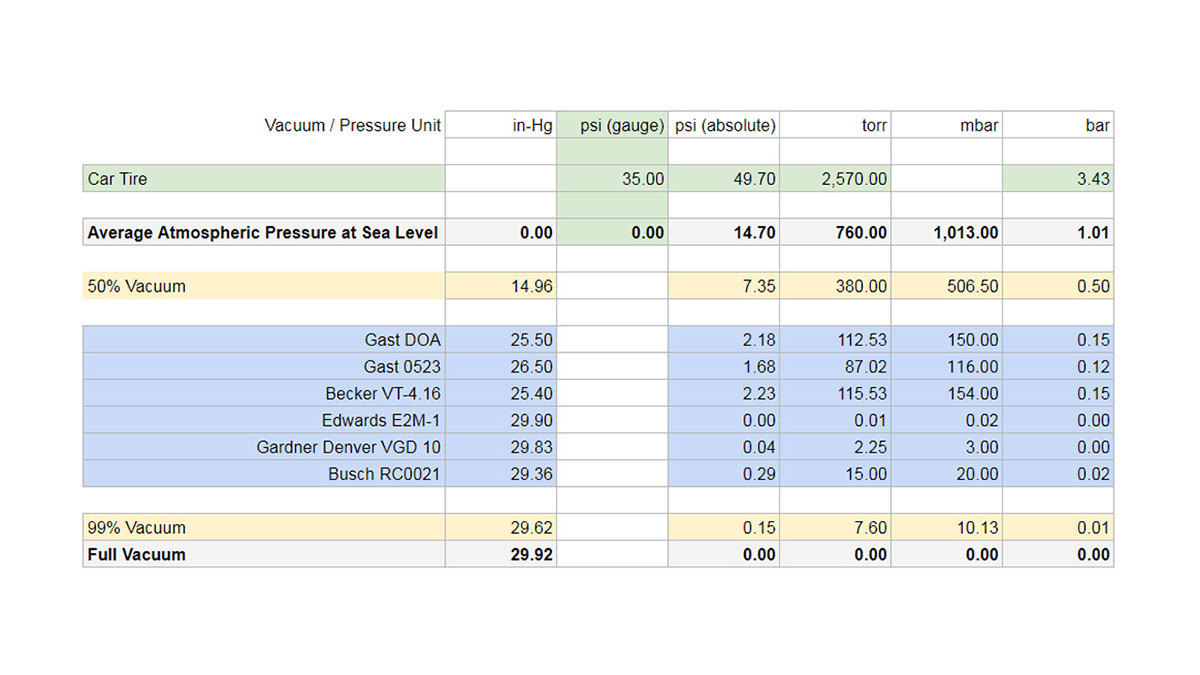

Vacuum is measured by comparing the pressure inside the measured volume (vacuum bag) with either the air outside (atmospheric pressure) or absolute pressure (absolutely no air) with either a relative gauge or absolute gauge. Absolute gauges are more repeatable because the atmospheric pressure changes with the weather. Unless you are fussy or have a specific application, an absolute gauge is probably not necessary for basic bagging. I’ll get back to gauges later on. Here is a graphic that shows pressure and vacuum in commonly used units of measure:

Most vacuum pumps and gauges will use either torr, inches of mercury (inHg) or millibar (mbar). The capacity will be rated in cubic feet per minute (CF/M) or cubic meters per hour (CM/H). This is a theoretical capacity. Most pumps can perform to their rating only at “free air” or no-load condition. As the vacuum level increases, the pump has to pull harder to remove air and the efficiency goes down. Many pump manufacturers publish a graph of this flow rate against vacuum level. Be mindful of this as you look at pumps and be sure to ask manufacturers (or consult datasheets online) to get an idea how much drop in flow to expect as vacuum levels increase. In practice, a bag will only get better as you remove leaks. The flow (CF/M) requirement will go down, allowing the vacuum level to go up. So practically it isn’t much of an issue but it is important to understand.

Use Cases

The type of pump best suited to you need and budget will depend on what you need it to do. Here are a few use cases and the types of pumps that would be well suited to the jobs:

1.) You are repairing a boat (it’s always a boat with me) that was damaged in a collision. You will need to vacuum bag some foam core and then several layers of fiberglass in epoxy resin. The bag will be about 25 square feet (2.5sq m.) and you need the do the job outside with a long extension cord. Here you don’t need lots of vacuum pressure, maybe only 10-15 inHg (500 mbar, 380 Torr) but the bag seal may not be perfect and a lot of it is overhead so you’ll want some capacity, maybe 10CFM or more. You could do with less, but if there are some leaks you could end up with less pressure than you need. Here a medium sized piston pump or diaphragm pump would be ok, but a nice dry rotary vane would be ideal. It will tolerate being moved around and can run on 110v (or whatever your wall-outlet power is) and a 1.5hp pump will pull 20+ inHg at 15 CFM or so. See the 110v Becker dry rotary pump in the video and charts below – it is perfect for this type of work.

2.) You have built some small cored panels, assembled them into a box and are laminating carbon fiber biaxial tapes at the joints to tie the panel skins together. Total length of the joint is a few feet (1m) and you are using two 12 oz (400gsm) tapes. You don’t need much of a pump here – maybe 10-20 inHg and a few CFM. This is a perfect place for a small diaphragm, piston or dry rotary vane pump. I have had several fractional horsepower diaphragm pumps that use 110v power and have a little handle and gauge on top and they are perfect for this. New ones are several hundred dollars but they can be found on Ebay and surplus sites for less. Both Gast pumps and the Becker from the video and charts below would be ideal for this.

3.) You are setting up a work-cell for a set of production infused parts with reusable silicone vacuum bags. The parts are not large, but you will be running several infusions in a rolling schedule and will be drawing down bags and shooting parts once every hour or two with a resin dispensing machine. This is a situation where two pumps are ideal. The overall cost of the pumps will be small compared to the rest of the tooling and equipment needed, and the cost of losing vacuum or interrupting production is high.

Often vacuum systems are set up with a high and a low vacuum manifold. The low vacuum (20-25 inHg or so) is plumbed to a high capacity pump (40+CFM) and is used to seat bags and to hold vacuum on parts after infusion is complete. The high vacuum is used before and during infusion and can be a smaller pump, but will most likely be an oil-lubricated rotary vane pump capable of pulling high vacuum (28-29 inHg.) In a production environment, high quality rotary vane pumps are a good choice. Oil-lubricated pumps require oil and filter changes and dry pumps need vanes replaced, but they can run for tens of thousands of hours with regular maintenance. With two pumps, each gets to do the job it does best and you don’t have to worry about the pressure under an active infusion dropping because somebody is pulling down a bag elsewhere in the factory.

4.) You are running a small shop making pre-preg automotive parts. You run a cook overnight and a small crew does layup and debulking during the day. Several parts are being debulked or bagged at any time and the vacuum demand is variable. For cooking, there needs to be enough volume to handle any moisture gracefully and as close to full vacuum as possible for optimal compaction. Debulking benefits from high volume to save time and high vacuum levels to really squish plies. In this case, the ideal pump would be a large (30+CFM, but maybe much larger) oil-lubricated rotary vane pump. None of the other options are going to cut it for pulling high levels of vacuum. You may (you definitely will) even want a dedicated cook pump for oven (or autoclave) operation, and so you have a backup. The Busch pump in the video and charts would be minimum-sized for this – a bigger version would be ideal.

Types of Pumps

There are several common types of vacuum pumps that make sense for composites applications. Here are short descriptions of each:

Diaphragm pumps are a lot like piston pumps except that they are often quieter – because instead of a piston they use a flexible diaphragm! You won’t get super high vacuum from a diaphragm pump but small ones are portable and you don’t have oil to deal with. Several companies make small ones that are handy for portable use. Check out the little Gast one in the video and charts. You can buy very fancy ones with multiple stages and high vacuum capacity but it probably makes more sense to buy a rotary vane pump if you are going over 1/2 HP.

Piston pumps are just like piston air compressors but backwards. Most can actually be hooked up as either compressors or vacuum pumps. They are simple and long lasting but don’t pull as much vacuum as a rotary vane pump. The ones I have used have been noisier that would be ideal, but they can often be found very cheap used. For small vacuum bagging jobs with wet laid material, a single phase piston pump would be fine.

Dry (oil-less) rotary vane pumps are a great option for higher volume (CFM) and medium vacuum level – say up to 25 inHg. They can run continuously and are easy to repair. Noise can be a problem – these are louder than oil lubricated pumps and if you are working in the same room with one all day you’ll notice. There is no oil to spill or get blown out all over the room though if there’s a big leak in your bag. Dry pumps also don’t mind having the vacuum level regulated down and will gladly run all day with air flowing through. The larger Gast and the Becker in the charts and video are this kind.

Oil-Lubricated Rotary Vane pumps – if you can get one, this is the best option for high vacuum. These pumps spin a set of vanes in an oil bath, so they can reach a much higher vacuum level than the other types listed here. Getting a relative gauge up to 29.9 inHg or an absolute gauge down near 0 (millibar, torr, kPa) is very possible with a good bag, good plumbing and a well maintained pump. The Gardner Denver, Busch and Edwards pumps in the video and charts are this kind. They don’t like having lots of air flowing through so it is best to only use an oil-lubricated rotary vane pump for very high vacuum. You can suck down bags with one but don’t hook it up to a regulator that bleeds air into the pump to reduce pressure – see oil issues below.

These pumps often have an oil filter (looks like a car oil filter) and an exhaust filter, which keeps the oil from blowing out with the exhaust air. When an oil-lubricated pump is run “open” with lots of air flowing through it, the oil can (and will) come out the exhaust in a fine mist. I recommend always plumbing the exhaust out of your work area (outside ideally) in case you have a bag pop or somebody forgets to close a valve. On more than one occasion I have seen a fog of oil mist fill a room. It is not healthy, and it is not good for all your clean oil-free work surfaces and materials. You’ll have to change the oil every few months (depending on usage) and if you are using materials that release moisture into the pump (cooking wood molds, etc.) your oil will get all frothy like a milkshake and you will need to change it more often. If you don’t change it and there is moisture, it will reduce the vacuum you can pull and also rust the insides of the pump.

Oil-lubricated rotary vane pumps can have a “gas ballast” which is usually found on high vacuum pumps – like the little Edwards in the video and the photos. This introduces a little bit of airflow that allows the pump to vent off water vapor or other contaminants coming out of the oil. It isn’t necessary or really all that helpful and pumps that have this feature are often too “high strung” for composites work and will fail sooner than a more standard duty pump. I killed off several of these nice “lab” type pumps before settling on simpler more appropriate types of pumps for composites. I would only use one of these for very high vacuum, low flow pre-preg use in a situation where there is little or no moisture from the materials or tooling.

Example Pumps

Of the oil-lubricated pumps shown in the video and the image above, the Edwards pump has no oil filter – and this makes it less suitable to general composites work. Lots of times you’ll run a pump with some flow-through – while debulking or sealing bags down – and this will cause oil to exit with the exhaust air. A pump with an exhaust oil filter – like the Gardner Denver and the Busch – will capture that oil and recirculate it rather than let it blow out. These pumps handle less-than-perfect bags better and provide more reliable service in a less then perfect industrial environment – so ideally this is what you should get for high-vacuum vacuum-bagging.

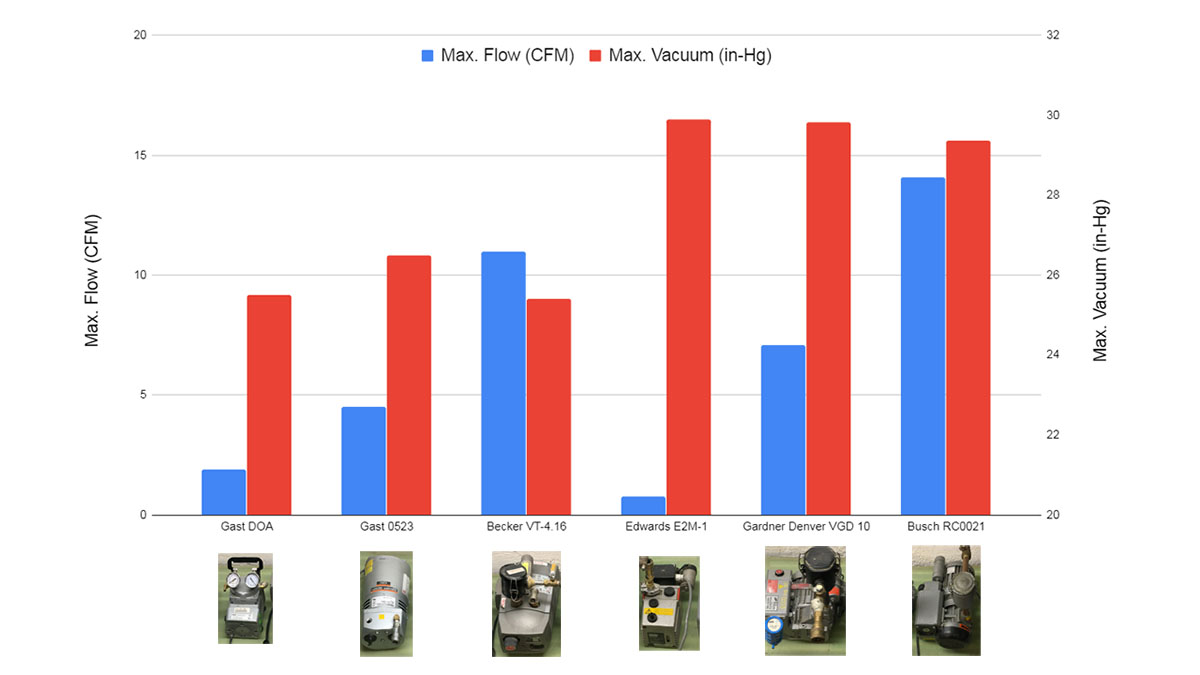

Here is a chart comparing the capacity and maximum vacuum of these six pumps. Capacity (CFM or M^3/HR) in blue is proportional to pump power – 0.16kW for the tiny Edwards and 0.90kW for the big Busch. Max. vacuum in red is a product of pump type – oil lubrication (three on the right) yields high vacuum.

And another below showing the maximum vacuum for each pump in several units – with some context. Green is positive pressure (car tire) and everything else is vacuum. Gauge pressure is relative to atmospheric pressure, where absolute pressure is… absolute.

Pumps for Vacuum Infusion

There are some special cases with vacuum infusion where you’ll want two very different things out of a vacuum pump – and my strong suggestion is that you get two different pumps! Infusion is really like two different processes stuck end-to-end when it comes to vacuum. First, you need to suck down your bag and pull all the volatiles and moisture out of your materials. This requires (ideally) really high vacuum. If you are a professional, here you will want the best high vacuum pump you can get – and a digital vacuum gauge to monitor it. You’ll run this pump right up until you are about to clamp off the resin feed lines after the part is full.

Now you switch your vacuum requirements to a much lower vacuum level. You still need to pull vacuum on the part, but if you keep the high vacuum going, any moisture or volatile components of the resin (MEKP or styrene for example – or moisture in the materials) will boil off and create bubbles. So now you want a low vacuum pump – maybe 20inHg or even lower. Here is where I’d recommend switching over to a oil-less (or “dry”) rotary vane pump that can handle running at reduced vacuum. The high-vac one will not like being regulated down to low vacuum if it means air will be flowing though. You can rig up regulators that don’t flow air through the pump, but standard ones will just bleed air into the line to reach the set level – which will be bad news for your fancy millibar-chasing vacuum-pulling oiled-rotary-vane suckin’ machine. If you’re serious about commercial level infusion my advice is to get two pumps – high and low.

This is mostly a consideration for disposable-bag type infusion. For reusable bag or Light RTM infusion, you may be dealing with a much lower cavity vacuum level if there is a vacuum clamp involved. But for low-volume disposable bag infusion with most resins (especially epoxy) you will have best results with a very high level of vacuum up front. Of course it works with lower vacuum levels (to a point) but you’ll have more to worry about.

And for really big parts, you may be fine just keeping the vacuum high throughout the cure… but if you’re doing that you should email me and tell me your opinion on this – no really!

More on all this in my Introduction to Vacuum Infusion and Troubleshootin’ Vacuum Infusion articles.

Pumps for Bagged Wet Layup

Generally bagged wet layup or core bonding is the least demanding of the types of vacuum bagging. Your first goal with the bag are to consolidate and clamp the material against the mold… or the part you’re secondary-bonding, or part you’re repairing. This doesn’t take much pressure! The second goal is to bleed off excess resin from a wet-out laminate. This can require more pressure – but nothing like prepreg or infusion.

For bedding core or consolidating a laminate without bleeding much resin you really need a pump that will pull a low vacuum. You want to be able to adjust the pressure level with a regulator. It isn’t unreasonable to use 5-10 inHg or 0.2-0.4 bar for low-bleed compaction. For higher performance laminates where you want to compact things and are using timing and perforated release film to limit over-bleed you could crank it up to 25 inHg or 0.85bar or more.

These low vacuum levels really rule out the oil-lubricated rotary vane pumps because they don’t do well running at reduced vacuum with air flowing through for hours. A dry rotary vane, diaphragm or piston pump with a regulator is ideal.

Pumps for Pre-pregs

For pre-preg processing you want as much vacuum as you can get. Most material datasheets will specify a minimum vacuum level for curing. This might be 25inHg / 0.85bar or so. More vacuum equals more compaction pressure and there are few reasons to use less pressure. Pre-pregs are meant to have the right amount of resin in them – or just enough extra that you can bleed them down to the desired volume or weight fraction.

I would suggest a oil-lubricated rotary vane pump for pre-pregs in almost every case. The vacuum level will be high and the pump will be quiet and reliable.

The only down-side might be if you are processing pre-pregs with wood-based tooling (MDF) or balsa cores or some other source of water vapor. You’d be amazed how much water and oven (or especially an autoclave) plus vacuum can pull out of a piece of wood! The pump will collect some of this vapor in the oil and it will get all frothy – which will reduce the ability of the pump to pull vacuum. Long term exposure to water can rust and damage the internal bits of the pump. You’ll want to keep an eye on your oil and change it regularly. Some pumps run at a higher temperature and are better suited (supposedly) to handling moisture. I had a Leybold Sogevac pump once that supposedly did this and it needed special oil – not sure how much it helped – but it was a nice pump.

For more about pre-pregs check out my article on Laminating with Pre-pregs.

Buying a Pump

What you choose to buy will have a lot to do with how much vacuum you need to pull, how much air you need to move and how much money you can spend. It is generally better to have too large a pump and one capable of pulling more vacuum than you really need – but you’ll run it a lot and it will use power.

If you are a professional user, you will want to have more than one, and they can be tailored to different kind of work. There’s no ideal one-size-fits-all vacuum pump! It is also good to have a backup if you are working on expensive parts because many processes are guaranteed to fail without vacuum – it’s cheap insurance.

Used vs. New

Vacuum pumps are pretty simple and the technology hasn’t evolved much in several decades – at least at the low end of the vacuum range where composites processing hangs out. Most large and established brands can provide spare parts for older pumps and routine rebuilds are not difficult as long as you are careful. Buying a used pump can be a great choice, and knowing how to maintain it yourself is always nice. I have bought several pumps on Ebay, and on Craigslist and from online surplus dealers like HGR Surplus. Sometimes you get trash and sometimes you get a deal. Overall, there are lots of perfectly good pumps available at auctions and factory closings. Usually the place didn’t go under because the vacuum pumps were junk – but you take your chances. Looking for common and well supported brands of pump is a good idea. Also before you bid, try to call up the brand’s service provider in your area and see about parts availability. Four of the pumps in the picture above were bought used for under $200 US. The Becker and Busch RC0021 were more.

Buying new is a good option if you are in a commercial situation where the vacuum pump plays a critical part in the commercial success of your work. Given how expensive composites materials are and how much labor contributes to most parts, it is not a good idea to risk it all on some rando pump from the internet. You’ll want support and parts, and probably you should get multiple pumps of the same model so you can have some parts and maintenance overlap.

Brands

Over the years I have owned more than a dozen vacuum pumps and have dealt with many dozens more that belonged to friends, customers or employers. A few were total crap. Some were great. Most worked very well until they were mistreated. The types of pumps you need for composites are different from what is required in labs and industrial “high vacuum” service. For this type of work you need good vacuum and really good durability – because you’re going to run it hard and put it away “wet” – often literally!

First off, please don’t get one of those refrigerant service pumps from Harbor Freight. They work. They spew oil all over if you run them open, and they get very hot. They also pull pretty good vacuum. I know of one that has been degassing resin daily for 5+ years. Ok, maybe they are an option worth considering if you need high vacuum on a tight budget. I would rather see you get a used Busch off Ebay – but one of these for a backup wouldn’t be a bad idea. Keep in mind they’re only meant to run for a few minutes at a time.

For small pumps, I have that Gast 1/8 hp diaphragm pump that has served me well for eight years. It has a switch and a handle and pulls 15-25 inHg at 1 CFM. It is perfect for little bags and repairs and dragging around on the end of an extension cord. Somebody also gave me a Gast piston pump that I “re-gifted” to a friend after tiring of the noise – super noisy! It was probably 20 years old when I got it and is probably still going somewhere out there. The rotary-vane Gast pump shown above is also nice, and it has more volume capacity – but it’s a little noisier.

My favorite size pump is the 1/2-2HP range. It can do small work all day long and if you’re careful you can infuse something 25 feet (8m) long no problem. I’d rather have two of these than one 5hp pump. My favorites are the Becker dry rotary vane pump and a oil-lubricated Busch RA 0025 – which is 3 phase and not shown here. Both of them were bought used from surplus dealers – and for substantially under $1000 total. The Busch gets its oil changed now and then and the Becker I haven’t touched.

When I had a small factory, we had Busch, Becker, Airtech and Leybold pumps that were slightly larger and they were very reliable and easy to deal with. Many manufacturers make multiple versions of the same pump with different performance specifications – like the older Busch RA, RB and RC designations. Check the tag and look up the datasheet if you need specific performance – like very high vacuum for debulking infusion stacks or high vapor handling for cooking MDF molds in an autoclave. I have killed (or mortally wounded) several pumps by using them to cook MDF which generates lots of water vapor that condenses in the oil. Lesson: you’ve got to change the oil when it looks like clam chowder.

As you get into bigger pumps, it starts to make more sense to buy new. If you need a 7hp vacuum pump for composites work, you have something going on and you know better than I do what you want. I have used larger Busch, Becker, Leybold and Rietschle pumps and they were all excellent. One company worth looking at if you are in a manufacturing environment is Vacmobiles in NZ. They don’t make actual pumps but they set them up on carts with manifolds and catch-pots. You pay extra for the convenience, but the concept and execution is excellent. I have used them at work and always wanted one for myself but been too cheap to get one! If you can’t afford their units, you can certainly use them for inspiration in building your own.

Power and Setup

If you bought a 3-phase pump, you need to make sure the motor runs in the right direction. Running a pump backwards is super bad for it – it ruins the vanes and you’ll need to rebuild it. This applies to rotary vane pumps – oil-less and oil-lubricated. Give the pump a tiny burst of power and see which way it goes. Swap legs if you have it wrong. Electricians will know this procedure and most pumps are marked with a rotation direction on the casting.

If you bought an oil-lubricated pump and it was shipped to you, chances are the shipper removed the oil – or at least they should have! You’ll have to replace the oil with new oil before you run it. Don’t run your pump without oil in it. You can give it a quick bump to make sure its going the right way before the electrician leaves, but nothing more. And make sure you get the right oil for your pump. Some high-vacuum pumps run hot to boil off moisture and need special oil. Check your manufacturer’s suggestions. For run-of-the-mill pumps, a standard vacuum pump oil is probably fine.

You should plumb the exhaust from your pump outside, especially with an oil-lubricated pump. The vacuum exhaust is all the air that came out from under the bag, so it can include volatiles from the resin. You should ideally not breathe this. With an oil-lubricated pump the exhaust will include oil mist if the pump is run at less than full vacuum for much time. Again, air flowing through this type of pump is not ideal. Worst case if you have a leak in a bag or a fitting come disconnected, your pump can exhaust oil mist for hours – filling up the air with a haze of micro oil droplets that contaminate everything with oil. Bad news!

Other Equipment

Once you have that vacuum pump, you are going to need a bunch of other stuff too. There are a wide range of hose and gauge options as well as ways to get the vacuum into the bag. Vacuum leaks are a big problem, especially in the fittings and hoses in you vacuum system because they will be a constant drain on your vacuum performance. You want to use thread sealant on each assembly and buy decent couplers. I use brass (less corrosion than steel and cheaper than stainless) Parker ISO-B style couplers for small hoses and either big ISO-B fittings or Cam-lock style connectors for larger hoses. There are lots of other better and worse options. Generally you get what you pay for!

For room temperature use, heavy-duty air hose is fine for vacuum if you’re not shooting for high performance. You can often go to your local hydraulic hose maker and have them spec. and crimp custom hoses for a surprisingly reasonable price. McMaster Carr sells (you can also buy by the roll and have your hose-maker use this) a yellow vacuum-rated Gorilla-brand hose that works great at room temperature. For high temperature oven or autoclave use you will pay more money but its worth getting the right kind of hoses. Cheap hoses flatten and lose flow when you heat them up. I have bought high temperature cook and autoclave hoses from Torr Technologies and Airtech and both are very good. Wire-reinforced silicone radiator hose works too. Torr makes some crazy rugged metal sheathed hoses – but I haven’t used them.

Here’s my article on Vacuum Stuff: Hoses, Fittings and Accessories.

Conclusions

If you are looking to get a first vacuum pump or to do simple vacuum bagging then a smaller oil-less pump – piston, diaphragm, or rotary vane would be a good place to start. If you can afford it, get a new or lightly used one. After a few months you’ll have developed opinions on what your next pump should be.

For small shops or hobbyists looking for a good quality pump for either high (oil) or lower (oil-less) vacuum, a rotary vane pump is a good choice. Better to buy three used ones for $1500 total and have two that work than to spend $2500+ on one new one and not have a backup. Bigger pumps are available used too – often at even steeper discounts because they are huge and need three-phase power.

If you’re relying on a vacuum pump for your day-to-day commercial activities – or your boss asked you to buy one – it’s probably safer to buy a new one and the support and warranty that comes with. Get something common and high quality and then keep an eye out for a used one of the same model. Vacuum is where the rubber meets the road for a lot of composites processing techniques. Consider the cost of even a single failed part, and bake that into your decision.

Vacuum bags are an almost magical tool – you can press really hard on things in ways no other clamping mechanism can match. The amount of vacuum you pull is directly proportional to the pressure on your work so you’ll need a pump that lets you get what you need. Different processes have very different requirements. Do your research, shop around – talk to people and ask questions. Over time try to round up a small collection if you do routine composites work. They’re like hammers – different types and sizes for different jobs!

Updates and Changes

Updated 12/18/19: section on power hookup and oil removal for shipping, misc grammatical, spelling edits.

Updated 4/29/20: edits and TOC

Updated 6/17/20: video integration, example pumps and pics

Updated 1/13/21: wet layup and infusion sections – links and better heading layouts

Updated 5/6/21: smaller graphics, PNG for sketches, lower quality jpegs, no embedded youtube – just link with picture

Note

This article contains information that reflects my opinions – I make no promises about its usefulness! It may contain mistakes (please let me know if you find some!) and will include prejudices based on my limited experience. If you disagree with anything here, please get in touch. This is not just for me to share what I know, but to learn from others. I will gladly insert additional information and differing opinions so readers are more aware of the diversity of “right” answers!