Project by North Shore Composites (2015)

What’s a Chainplate?

Chainplates are the pieces of structure that all the rigging is attached to – they keep the mast standing up. There’s a lot of load on them! These were bonded into a heavily reinforced part of the hull of the boat, and the bushings poke up though the deck to connect to the rigging.

- More on pre-preg laminating here: Laminating With Pre-pregs

The Process

The upper part (red in the sketch) is solid prepreg iso-plate. The rest of the body of the chain-plate is a foam-cored tapered panel. This was pre-cured and bonded to the machined carbon wedge. Bushings were bonded to the solid carbon wedge. A light laminate was applied and cooked to tie these pieces together. Next the strap laminate was laid up and debulked every few plies. This was carefully bagged and cooked.

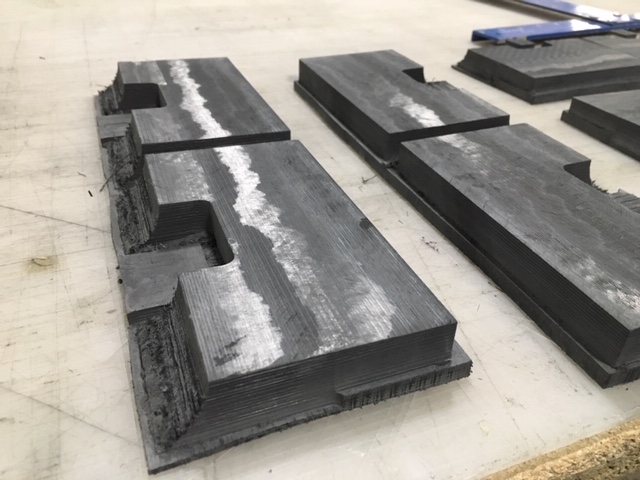

Solid isoplate carbon saddles rough machined.

Foam cored base “wedge” – prepreg skins on high density core.

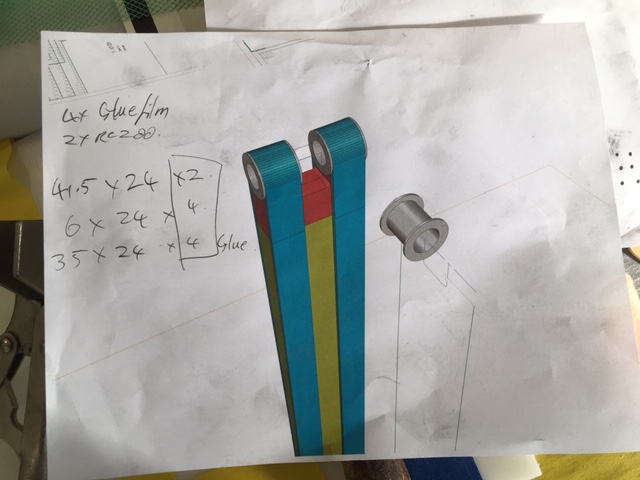

Pictures are always good! I like to prints views of 3D models with color coding.

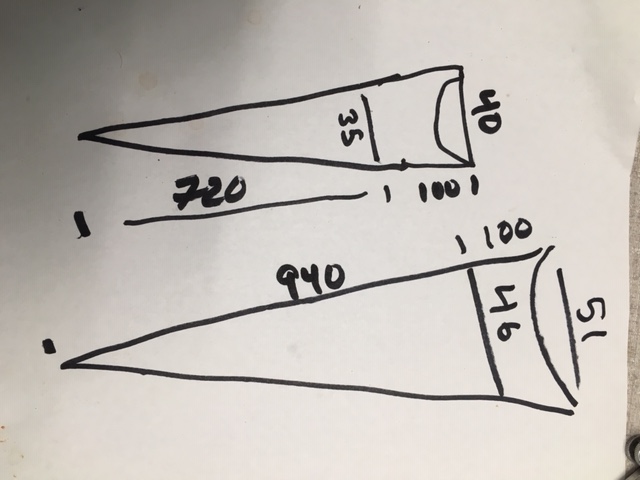

Also, quick sketches with dimensions to check against machined parts.

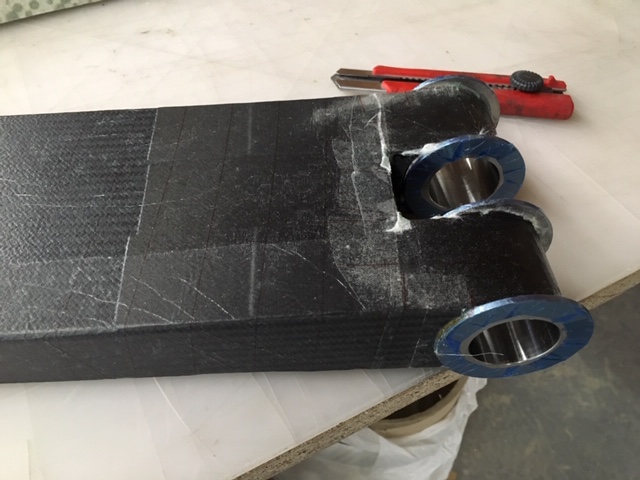

Bonding solid carbon to wedge.

Bonding bushings to the wedges. Dummy pins keep things aligned.

Light lamination and cook to hold things together. Still always cook with dummy pin in place.

Laminating unidirectional straps up and over the bushings. Lots of layers and debulking!

Woven layers intermittently at +/- 45 degrees to the uni.

Careful peel-ply. Prepreg on the bushings, dry on the rest. Note the peel ply cut on the bias.

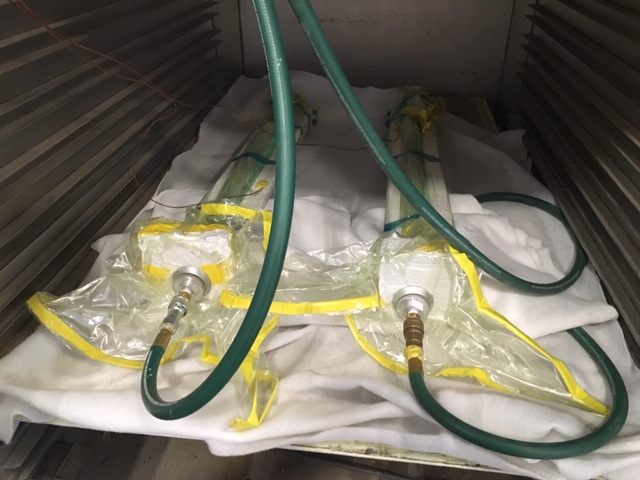

Cook bags on with peel ply straps up and over the bushing ends to prevent wrinkles.

Bag gathered into tidy pleats so wrinkles in the bag don’t cause trouble.

Thermocouples – check, padding – check, vacuum – check. Light the oven!

Cured parts. The area between the stacks of strapping is filled with laminate to make a flat bonding surface.

Peel ply stays on until the last minute. These are ready to head to the boat.

I am not sure how much load these take, but it is probably a lot. The key concern here is making sure everything is neat and clean and there are no wrinkles. The straps of unidirectional carbon taper out as they go down the wedge, but there are probably 35 layers going over the bushings. It is also important to keep the bushings aligned. Each time these were cooked, the pins (or dummy pins coated with release) were in place so things wouldn’t shift during the cook.