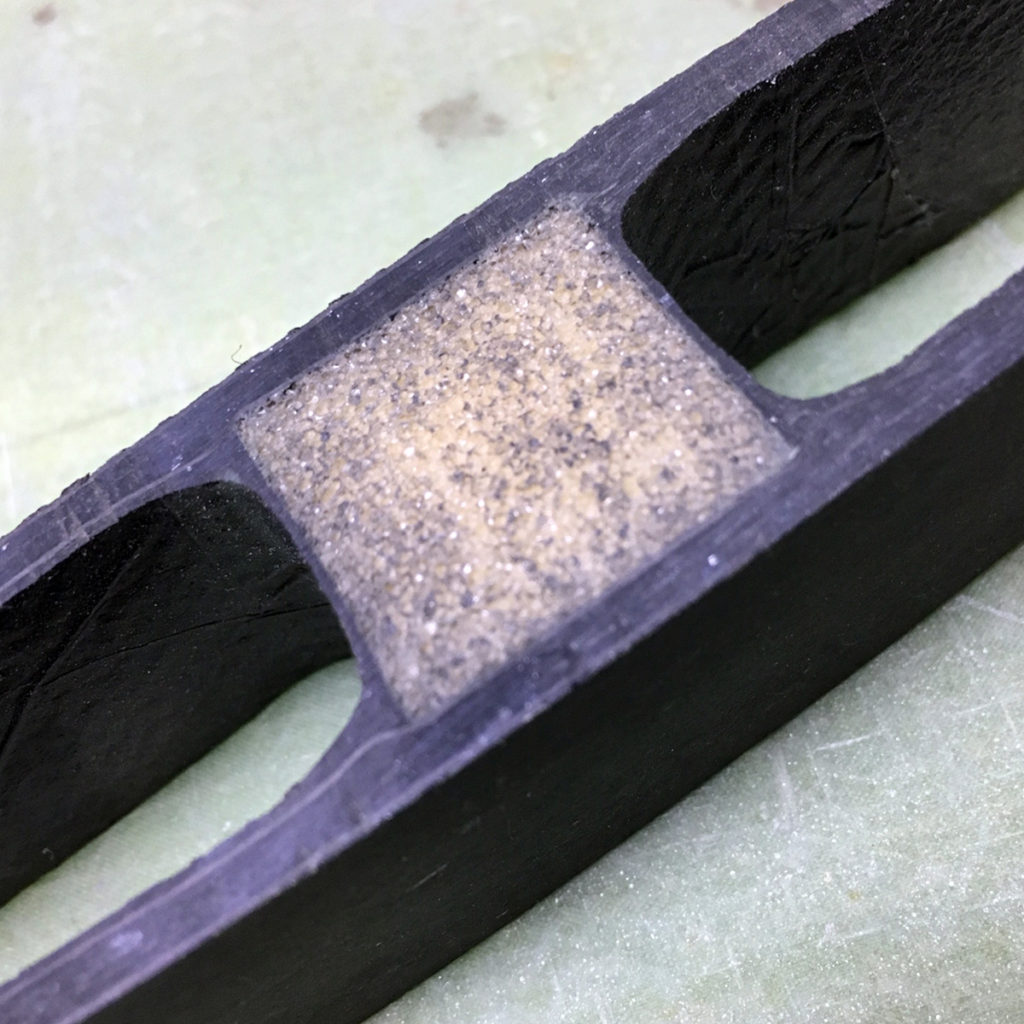

I was cleaning out a toolbox and found this off-cut from an old test – from maybe 2008 or so. This was when I first had a CNC router and was working on making small daggerboards for a sailboat. This was a test of a one-cook section of foil – maybe 250mm front to back and 25mm thick. The test was only 300mm long and I have no idea where the rest went – but this small section survives.

After some consideration I ended up doing the parts a different way, but I went back and searched through my photos and found that I had carefully (for me) documented the layup and bagging process. The bagging is a neat example of using internal and external vacuum bags – in this case tube-bag. You can see the wavy fiber in the close-ups of the part which would have been prevented by pre-curing the skins of each half – but this was an attempt to mold and cure the whole thing at once.

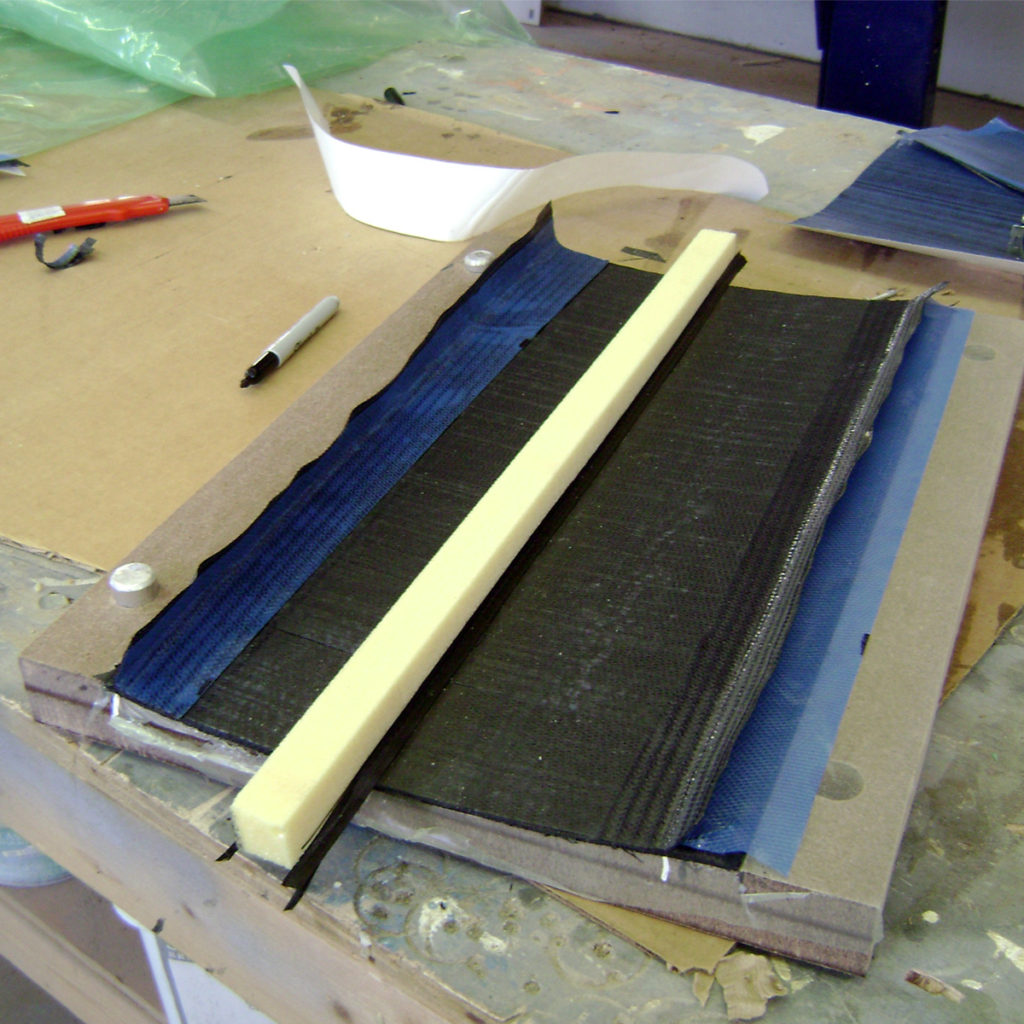

Starting with some MDF molds – pretty sure I covered them with adhesive teflon.

Laying up the base laminate from carbon uni.

Debulking the base laminate to the mold. I am using tube-bag and instead of sealant – just folding the end over a bunch of times.

Foam shear-web former. The +/-45 degree carbon strips on the front and back will fold around to tie the halves together.

More +/-45 strips form the shear webs on either side of the foam. Release film will separate the bag from the carbon.

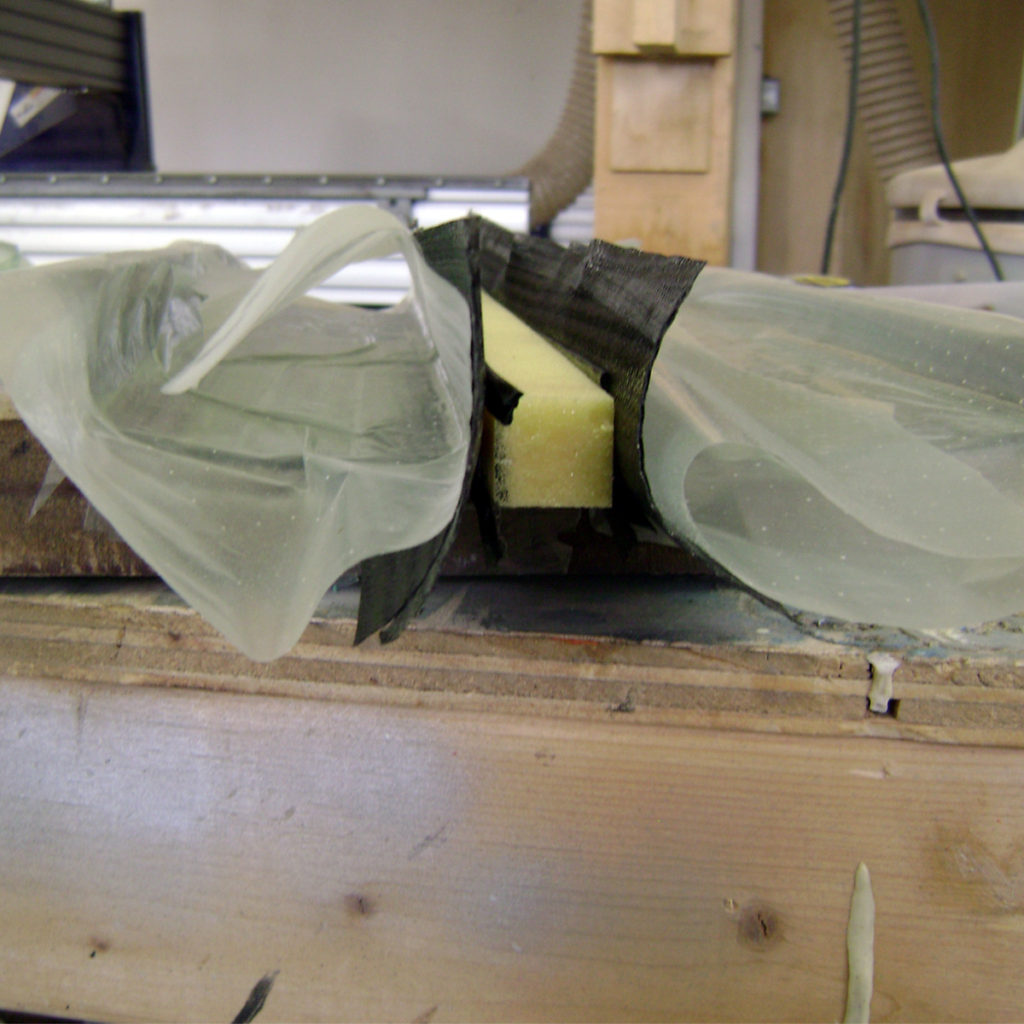

End view of the shear web with strips of unidirectional material rolled up to form fillets at the corners.

The first piece of tube bag in. The release film gets folded over the bag and the carbon folded over the release film before the other half (with just base laminate) is dropped on.

Two internal bags and breather over the outside.

Outside bag connected to inside bag – like a two-holed doughnut.

Cooked part sliced to show shear web zone. Note wrinkled fibers.

Trailing edge with wrinkled fiber visible.

Finished foil section

Certainly not an ideal outcome, but pretty interesting to see the way the fiber behaved – and a good way to illustrate the inside/outside bagging method and tying two halves of a part together with +/-45 degree strips of pre-preg. This was before I had an autoclave – but it would be neat to test this concept again with more pressure!